An Overview on MIM Component

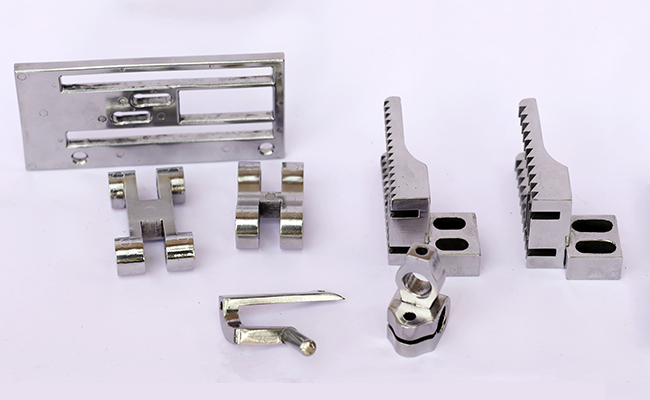

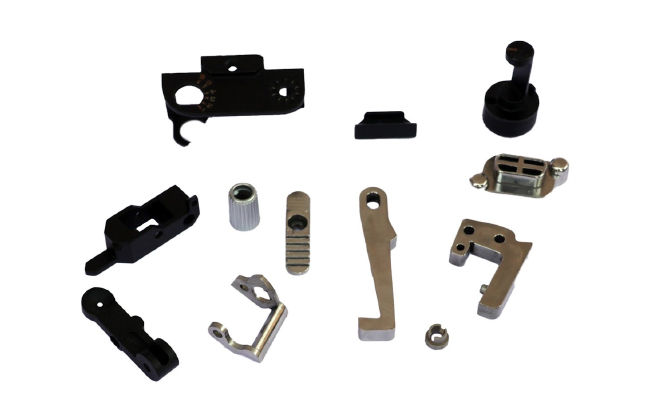

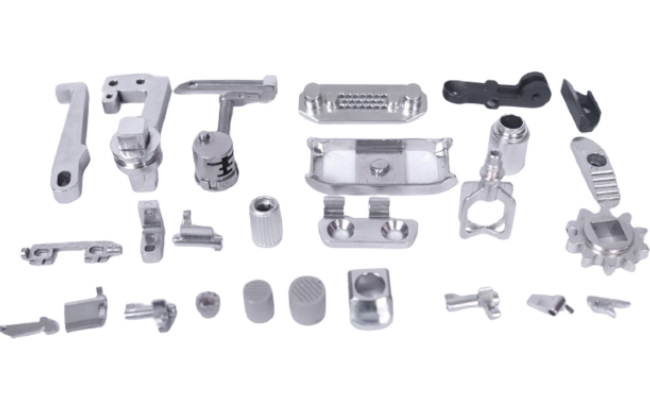

MIM is a pioneering technology that merges the benefits of plastic injection molding with the material properties of metals. This advanced process is revolutionizing the manufacturing industry, especially in the production of small, complex and high volume components.

A MIM Components is a metal part produced using the Metal Injection Molding Process. This process involves mixing fine metal powders with a binder material to create a feedstock, which is then injected into a mold to form the desired shape. After molding, the binder is eliminate and the component is sintered at high temperatures to achieve its final density and strength.